English

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Română

Română Slovenski

Slovenski Српски

Српски Afrikaans

Afrikaans Беларус

Беларус Hrvatski

Hrvatski Монгол хэл

Монгол хэл Zulu

Zulu Somali

Somali O'zbek

O'zbek Hawaiian

Hawaiian

Consume Grade Phototransistor Optocoupler OR-3H7-EN-V13

Consume Grade Phototransistor Optocoupler OR-3H7-EN-V13 Consume Grade Phototransistor Optocoupler OR-3H7-4-EN-V3

Consume Grade Phototransistor Optocoupler OR-3H7-4-EN-V3 Consume Grade Phototransistor Optocoupler OR-3H4-EN-V12

Consume Grade Phototransistor Optocoupler OR-3H4-EN-V12 Consume Grade Phototransistor Optocoupler OR-3H4-4-EN-V3

Consume Grade Phototransistor Optocoupler OR-3H4-4-EN-V3 Consume Grade Phototransistor Optocoupler ORPC-817-S-(SJ)

Consume Grade Phototransistor Optocoupler ORPC-817-S-(SJ) Consume Grade Phototransistor Optocoupler ORPC-817-S-(SJ)-EN-V0

Consume Grade Phototransistor Optocoupler ORPC-817-S-(SJ)-EN-V0- All new products

Darlington Optocoupler ORPC-815-EN-V5

Current transfer ratio(( CTR : MIN. 600% at IF = 1mA, VCE = 2V,Ta=25℃)

Product Description

Darlington Optocoupler

Features

- Current transfer ratio(( CTR : MIN. 600% at IF = 1mA, VCE = 2V,Ta=25℃)

- High input -output isolation voltage (VISO=3,750Vrms)

- High collector-emitter voltage (VCEO =35V)

- Working Temperature -55 ℃ to 110 ℃

- SOP-4 package

- Safety approval

- UL approved(No.E323844)

- VDE approved(No.40029733)

CQC approved (No.CQC19001231256) - In compliance with RoHS, REACH standards

- MSL Class Ⅰ

Instructions

-

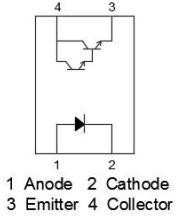

The OR-355 series device contains an infrared emitting diodes, optically to a photo Darington detector.They are encapsulated in a 4 pin SOP encapsulation.

-

Pin pitch of OR-355 is 2.54mm

Application Range

-

Hybrid substrates that require high density mounting.

-

Programmable controllers

-

System appliance, measuring instruments

Max Absolute rated Value (Normal Temperature=25℃)

|

Parameter |

Symbol |

Rated Value |

Unit |

|

|

Input |

Forward Current |

IF |

50 |

mA |

|

Junction Temperature |

TJ |

125 |

℃ |

|

|

Reverse Voltage |

VR |

6 |

V |

|

|

Consume Power |

P |

100 |

mW |

|

|

Output |

Collector and emitter Voltage |

VCEO |

35 |

V |

|

Emitter and collector Voltage |

VECO |

6 |

||

|

Collector Current |

IC |

80 |

mA |

|

|

Consume Power |

PC |

150 |

mW |

|

|

Total Consume Power |

Ptot |

200 |

mW |

|

|

*1 Insulation Voltage |

Viso |

3750 |

Vrm s |

|

|

Working Temperature |

Topr |

-55 to + 110 |

℃ |

|

|

Deposit Temperature |

Tstg |

-55 to + 125 |

||

|

*2 Soldering Temperature |

Tsol |

260 |

||

*1. AC Test, 1 minute, humidity = 40~60% Insulation test method as below:

-

-

Short circuit both terminals of photo coupler.

-

No Current when testing insulationvoltage.

-

Adding sine wave voltage when testing.

-

*2. soldering time is 10 seconds.

Opto-electronic Characteristics

|

Parameter |

Symbol |

Min |

Typ.* |

Max |

Unit |

Condition |

|

|

Input |

Forward Voltage |

VF |

--- |

1.1 |

1.4 |

V |

IF=20mA |

|

Reverse Current |

IR |

--- |

--- |

5 |

µA |

VR =5V |

|

|

Terminal Capacitance |

Ct |

--- |

30 |

250 |

pF |

V=0, |

|

|

Output |

Collector Dark Current |

ICEO |

--- |

--- |

1 |

µA |

VCE=20V, IF=0 |

|

Collector-Emitter Breakdown Voltage |

BVCEO |

35 |

--- |

--- |

V |

IC=0.1mA, IF=0 |

|

|

Emitter-Collector Breakdown Voltage |

BVECO |

6 |

--- |

--- |

V |

IE=0.1mA, IF=0 |

|

|

Transforming Characteristics |

1.Current Transfer Ratio |

CTR |

600 |

--- |

7500 |

% |

IF=1mA, VCE=2V |

|

Collector Current |

IC |

6 |

--- |

75 |

mA |

||

|

Collector-Emitter Saturation Voltage |

VCE(sat) |

--- |

--- |

1 |

V |

IF=20mA, IC= 5mA |

|

|

Insulation Impedance |

Riso |

5×1010 |

1×1011 |

--- |

Ω |

DC500V 40~60%R.H. |

|

|

Floating Capacitance |

Cf |

--- |

0.6 |

1 |

pF |

V=0, |

|

|

Response Time(Rise) |

tr |

--- |

200 |

--- |

μs |

VCC=5V, IC=2mA, RL=100Ω |

|

|

Descend Time(fall) |

tf |

--- |

200 |

--- |

μs |

||

-

Current Conversion Ratio = IC / IF × 100%

Rank table of current transfer ratio CTR(tolerance:±3%)

|

MODEL NO. |

CTR Rank |

Min. |

Max. |

Unit |

Condition |

|

OR-355 |

NO mark |

600 |

7500 |

% |

IF=1mA, VCE=2V, Ta=25℃ |

Order Information

Part Number

OR-355-X-Y-Z

Note

X = Tape and reel option (TP or TP1).

Y = ‘V’ code for VDE safety (This options is not necessary). Z = ‘G’ code for Halogen free.

* VDE Code can be selected.

|

Option |

Description |

Packing quantity |

|

TP |

Surface mount lead form (low profile) + TP tape & reel option |

3000 units per reel |

|

TP1 |

Surface mount lead form (low profile) + TP1 tape & reel option |

3000 units per reel |

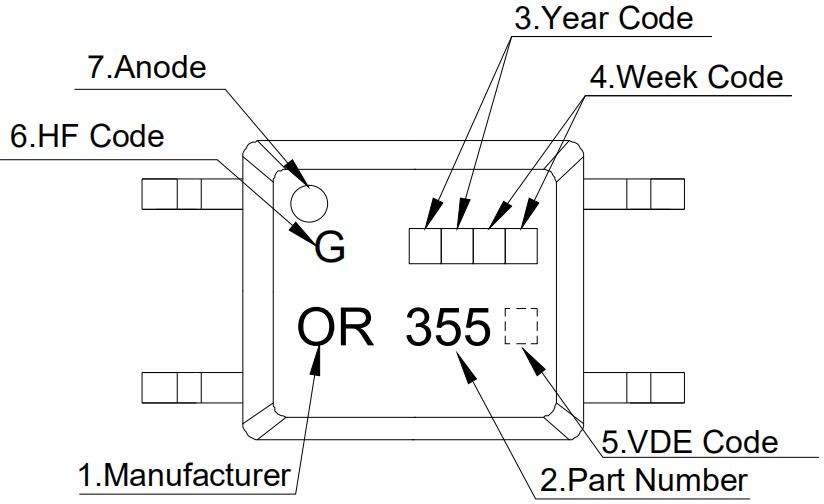

Naming Rule

-

Manufacturer : ORIENT.

-

Part Number : 355.

-

Year Code

: '21' means '2021' and so on.

: '21' means '2021' and so on. -

Week Code

: 01 means the first week, 02 means the second week and so on.

: 01 means the first week, 02 means the second week and so on. -

VDE Code

. (Optional)

. (Optional) -

HF Code ‘G’: Halogen Free.

-

Anode.

- VDE Code can be selected.

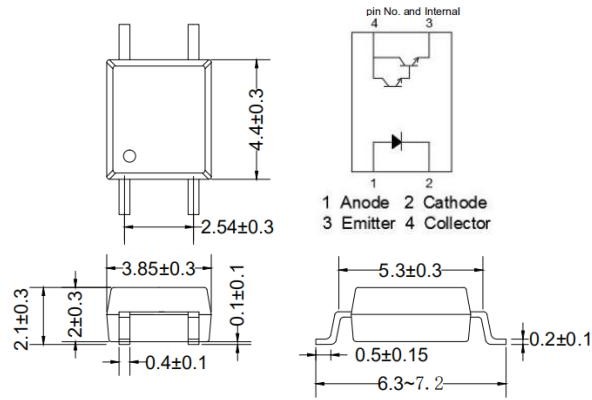

Outer Dimension

-

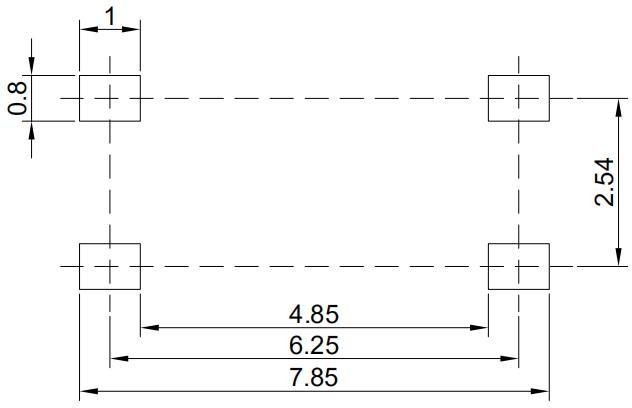

Recommended Foot Print Patterns (Mount Pad)

unit:mm

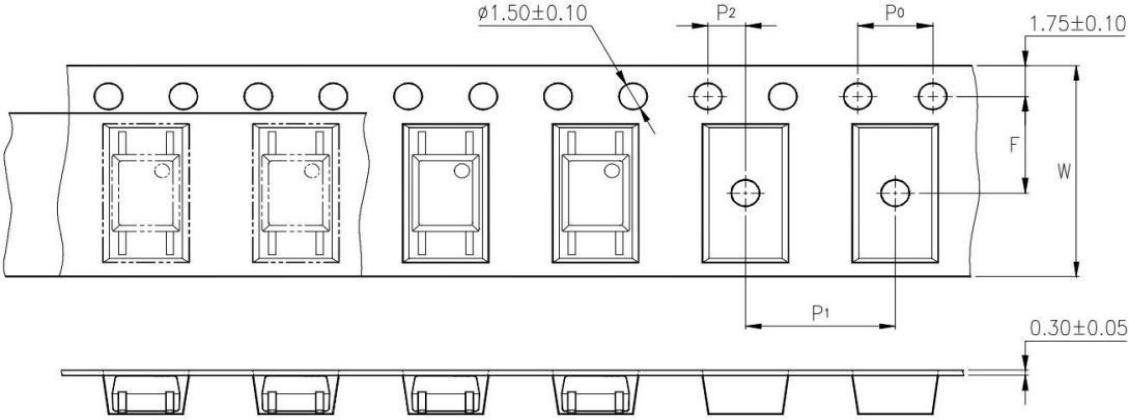

Taping Dimensions

(1)OR-355-TP

2.54±0.1

(2)OR-355-TP1

|

Description |

Symbol |

Dimension in mm(inch) |

|

Tape wide |

W |

12±0.3(0.472) |

|

Pitch of sprocket holes |

P0 |

4±0.1(0.157) |

|

Distance of compartment |

F |

5.5±0.1(0.217) |

|

P2 |

2±0.1(0.079) |

|

|

Distance of compartment to compartment |

P1 |

8±0.1(0.315) |

|

Package Type |

TP/TP1 |

|

Quantities(pcs) |

3000 |

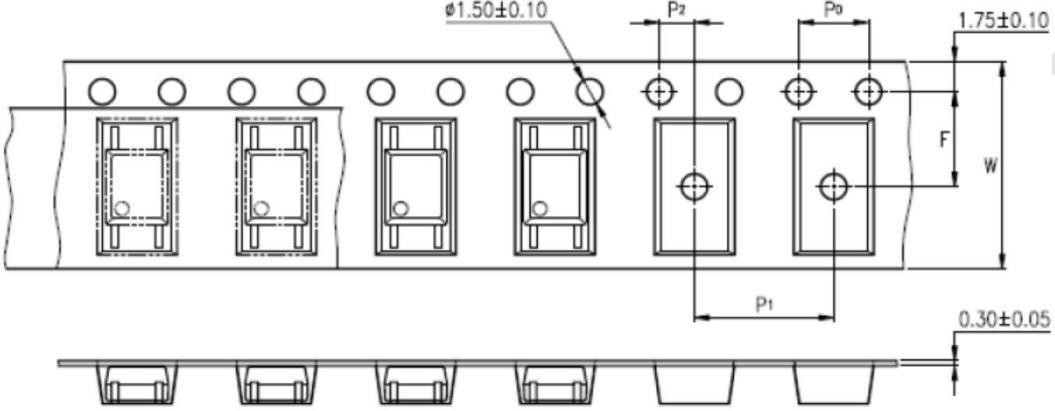

Package Dimension

|

Packing Information |

|

|

Packing type |

Reel type |

|

Tape Width |

12mm |

|

Qty per Reel |

3,000pcs |

|

Small box (inner) Dimension |

345*345*45mm |

|

Large box (Outer) Dimension |

480x360x360mm |

|

Max qty per small box |

6,000pcs |

|

Max qty per large box |

60,000pcs |

Packing Label Sample

Note:

-

Material Code :Product ID.

-

P/N :Contents with "Order Information" in the specification.

-

Lot No. :Product data.

-

D/C :Product weeks.

-

Quantity :Packaging quantity.

Reliability Test

-

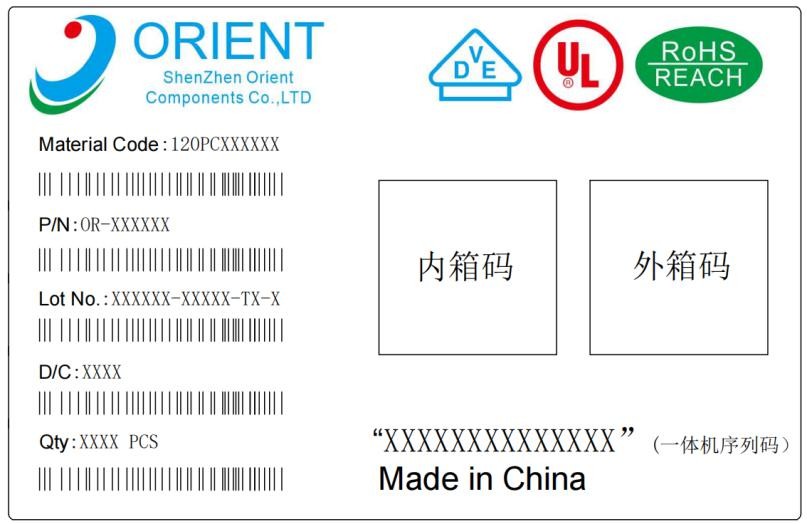

Temperature Profile Of Soldering

-

IR Reflow soldering (JEDEC-STD-020C compliant)

One time soldering reflow is recommended within the condition of temperature and time profile shown below. Do not solder more than three times.

|

Profile item |

Conditions |

|

Preheat

- Time (min to max) (ts) |

150˚C |

|

Soldering zone |

217˚C |

|

Peak Temperature |

260˚C |

|

Peak Temperature time |

20 sec |

|

Ramp-up rate |

3˚C / sec max. |

|

Ramp-down rate from peak temperature |

3~6˚C / sec |

|

Reflow times |

≤3 |

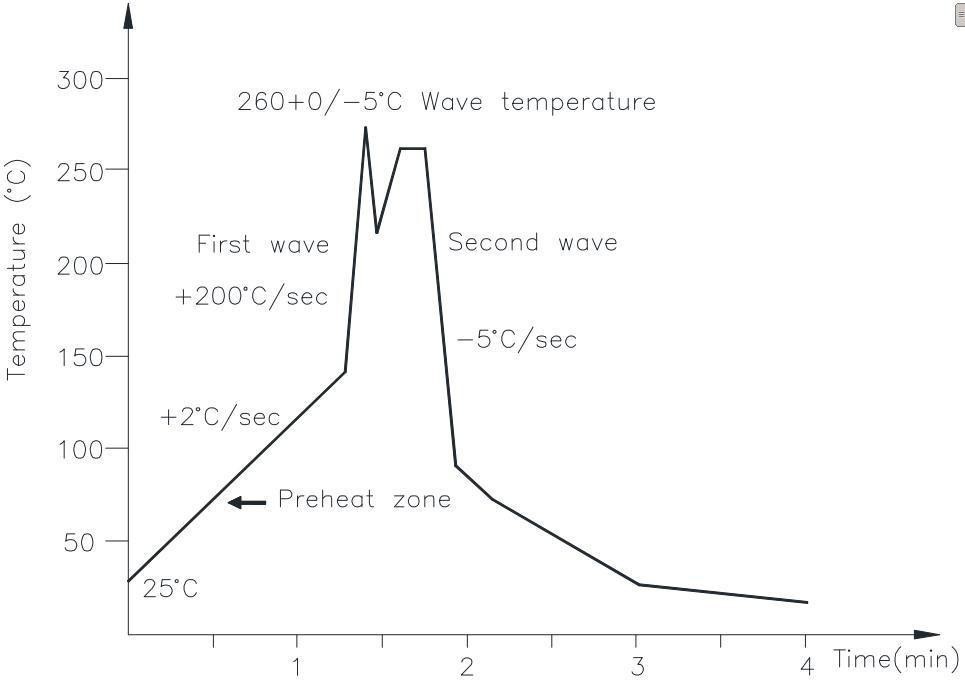

Wave soldering (JEDEC22A111 compliant)

One time soldering is recommended within the condition of temperature.

|

Temperature |

260+0/-5˚C |

|

Preheat temperature |

5 to 140˚C |

Hand soldering by soldering iron

Allow single lead soldering in every single process. One time soldering is recommended.

3 sec max

380+0/-5˚C

Time

Temperature