English

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Română

Română Slovenski

Slovenski Српски

Српски Afrikaans

Afrikaans Беларус

Беларус Hrvatski

Hrvatski Монгол хэл

Монгол хэл Zulu

Zulu Somali

Somali O'zbek

O'zbek Hawaiian

Hawaiian

Consume Grade Phototransistor Optocoupler OR-3H7-EN-V13

Consume Grade Phototransistor Optocoupler OR-3H7-EN-V13 Consume Grade Phototransistor Optocoupler OR-3H7-4-EN-V3

Consume Grade Phototransistor Optocoupler OR-3H7-4-EN-V3 Consume Grade Phototransistor Optocoupler OR-3H4-EN-V12

Consume Grade Phototransistor Optocoupler OR-3H4-EN-V12 Consume Grade Phototransistor Optocoupler OR-3H4-4-EN-V3

Consume Grade Phototransistor Optocoupler OR-3H4-4-EN-V3 Consume Grade Phototransistor Optocoupler ORPC-817-S-(SJ)

Consume Grade Phototransistor Optocoupler ORPC-817-S-(SJ) Consume Grade Phototransistor Optocoupler ORPC-817-S-(SJ)-EN-V0

Consume Grade Phototransistor Optocoupler ORPC-817-S-(SJ)-EN-V0- All new products

Consume Grade Phototransistor Optocoupler ORPC-817-S-(SJ)

ORPC-817-(SJ) photo coupler consist of one piece of GaAs emitter and one piece of NPN transistor.

Product Description

Phototransistor Optocoupler

Features

-

Current transfer ratio ( CTR : MIN. 50% at IF = 5mA, VCE = 5V )

-

High input-output isolation voltage ( Viso = 5,000Vrms )

-

Response time ( tr : TYP. 4µs at VCE = 2V, IC = 2mA, RL = 100Ω)

-

ESD pass HBM 8000V/MM 2000V

-

Safety approval

UL approved (No.E323844) VDE approved(No.40029733)

CQC approved (No.CQC09001029446) CE approved (No.AC/0431008)

State Grid approved (No.SGCM013420170152 )

-

In compliance with RoHS, REACH standards

-

MSL Class Ⅰ

Description

-

ORPC-817-S-(SJ) photo coupler consist of one piece of GaAs emitter and one piece of NPN transistor.

-

Packaged in a 4-pin DIP package and available in wide-lead spacing and SMD option.

Applications

-

Switching power supply

-

Ammeter

-

Computer

-

Instrumental application, measurement machine

-

Signal transforming systems

-

Imbursement equipments, duplicating machine, automat

-

Family-use electric equipments, such as fans

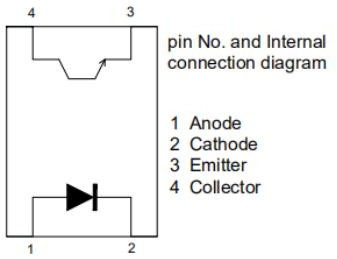

Functional Diagram

Absolute Maximum Ratings at Ta=25℃

|

Parameter |

Symbol |

Rated Value |

Unit |

|

|

Input |

Forward Current |

IF |

60 |

mA |

|

Peak forward Current (100μs pulse, 100Hz frequency) |

IFP |

1 |

A |

|

|

Reverse Voltage |

VR |

6 |

V |

|

|

Consume Power |

P |

70 |

mW |

|

|

Output |

Collector and emitter Voltage |

VCEO |

80 |

V |

|

Emitter and collector Voltage |

VECO |

7 |

||

|

Collector Current |

IC |

50 |

mA |

|

|

Consume Power |

PC |

150 |

mW |

|

|

Total Consume Power |

Ptot |

200 |

mW |

|

|

*1 Insulation Voltage |

Viso |

5,000 |

Vrms |

|

|

Max Insulation Voltage (Insulating oil test) |

VIOTM |

10,000 |

V |

|

|

Rated Impulse Insulation Voltage |

VIORM |

630 |

V |

|

|

Working Temperature |

Topr |

-55 to + 110 |

℃ |

|

|

Deposit Temperature |

Tstg |

-55 to + 125 |

||

|

*2 Soldering Temperature |

Tsol |

260 |

||

*1.AC For 1 Minute, R.H. = 40 ~ 60%

Isolation voltage shall be measured using the following method.

-

-

Short between anode and cathode on the primary side and between collector and emitter onthe secondary side.

-

The isolation voltage tester with zero-cross circuit shall be used.

-

The waveform of applied voltage shall be a sine wave.

-

*2. Soldering time is 10 seconds

Electro-Optical Characteristics (Ta=25℃ unless specified otherwise)

|

Parameter |

Symbol |

Min |

Typ.* |

Max |

Unit |

Condition |

|

|

Input |

Forward Voltage |

VF |

--- |

1.2 |

1.4 |

V |

IF=20mA |

|

Reverse Current |

IR |

--- |

--- |

5 |

μA |

VR=5V |

|

|

Collector Capacitance |

Ct |

--- |

30 |

250 |

pF |

V=0, f=1KHz |

|

|

Output |

Collector to Emitter Current |

ICEO |

--- |

--- |

100 |

nA |

VCE=20V, IF=0mA |

|

Collector and Emitter attenuation Voltage |

BVCEO |

80 |

--- |

--- |

V |

IC=0.1mA IF=0mA |

|

|

Emitter and Collector attenuation Voltage |

BVECO |

7 |

--- |

--- |

V |

IE=0.1mA IF=0mA |

|

|

Transforming Characteristics |

*1 Current conversion ratio |

CTR |

50 |

--- |

600 |

% |

IF=5mA VCE=5V |

|

Collector Current |

IC |

2.5 |

--- |

30 |

mA |

||

|

Collector and Emitter Saturation Voltage |

VCE(sat) |

--- |

0.1 |

0.2 |

V |

IF=20mA IC= 1mA |

|

|

Insulation Impedance |

Riso |

5×1010 |

1×1012 |

--- |

Ω |

DC500V 40~60%R.H. |

|

|

Floating Capacitance |

Cf |

--- |

0.6 |

1.0 |

pF |

V=0, f=1MHz |

|

|

Cut-off Frequency |

fc |

--- |

80 |

--- |

kHz |

VCE=5V, IC=2mA RL=100Ω,-3dB |

|

|

Rise Time |

tr |

--- |

4 |

18 |

μs |

VCE=2V, IC=2mA RL=100Ω |

|

|

Descend Time |

tf |

--- |

3 |

18 |

μs |

||

*1 Current Conversion Ratio = IC / IF × 100% , CTR Tolerance:±3%.

Rank Table of Current Transfer Ratio

|

CTR Rank |

Min. |

Max. |

Condition |

Unit |

|

L |

50 |

100 |

IF=5mA, VCE=5V, Ta=25℃ |

% |

|

A |

80 |

160 |

||

|

B |

130 |

260 |

||

|

C |

200 |

400 |

||

|

D |

300 |

600 |

Order Information

Part Number

ORPC-817XT-V-W-Y-Z-(SJ)

Note

X = Lead form option (S, M or none) T = CTR Rank (L, A, B, C, D or none)

V = Tape and reel option (TP,TP1 or none). W = Lead frame option (F: Iron)

Y = ‘G’ code for Halogen free (HF only). Z = ‘S’ process identification code.

SJ = Field code.

|

Option |

Description |

Packing quantity |

|

S(TP) |

Surface mount lead form (low profile) + TP tape & reel option |

2000 units per reel |

|

S(TP1) |

Surface mount lead form (low profile) + TP1 tape & reel option |

2000 units per reel |

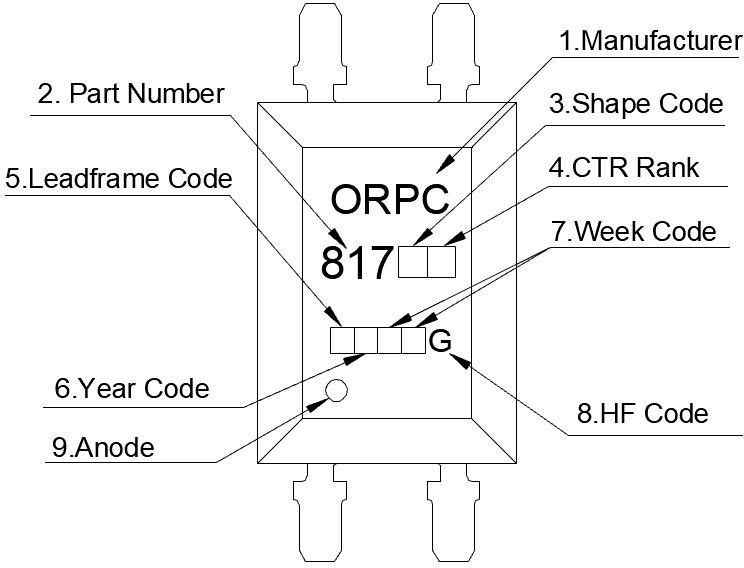

Naming Rule

-

Manufacturer : ORIENT.

-

Part Number : 817.

-

Shape Code

(M , S , or none) .

(M , S , or none) . -

Rank Code

: CTR Rank

: CTR Rank -

Lead frame Code

:‘F’ means Iron.

:‘F’ means Iron. -

Year Code

: '1' means '2021' and so on.

: '1' means '2021' and so on. -

Week Code

: 01 means the first week, 02 means the second week and so on.

: 01 means the first week, 02 means the second week and so on. -

HF Identification ‘G’ .

-

Anode.

-

Package Dimension (Unit:mm)

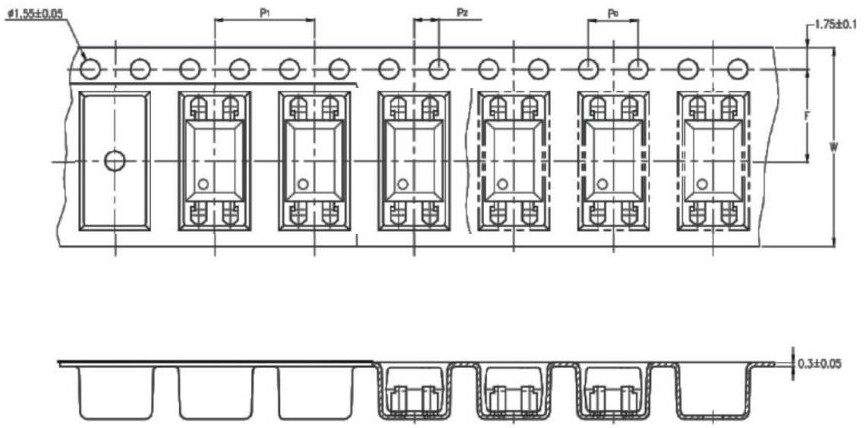

Taping Dimensions

(1)TP Type

(2)TP1 Type

|

Description |

Symbol |

Dimension in mm (inch) |

|

Tape wide |

W |

16±0.3 (.63) |

|

Pitch of sprocket holes |

P0 |

4±0.1 (.15) |

|

Distance of compartment |

F |

7.5±0.1 (.295) |

|

P2 |

2±0.1 (.0079) |

|

|

Distance of compartment to compartment |

P1 |

8±0.1 (.472) |

|

Package Type |

TP/TP1 |

|

Quantities(pcs) |

2000 |

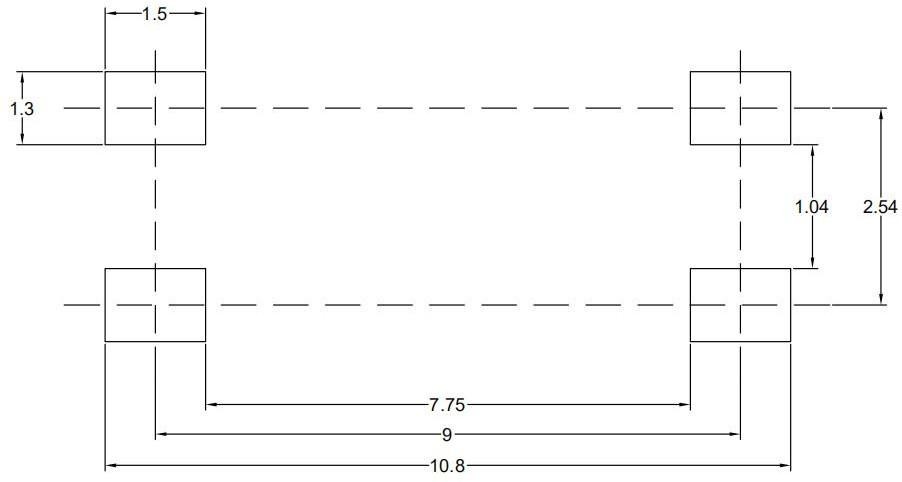

Recommended Foot Print Patterns (Mount Pad) (Unit:mm)

Package Dimension

SOP Type

|

Packing Information |

|

|

Packing type |

Reel type |

|

Tape Width |

16mm |

|

Qty per Reel |

2,000pcs |

|

Small box (inner) Dimension |

345*345*58.5mm |

|

Large box (Outer) Dimension |

620x360x360mm |

|

Max qty per small box |

4,000pcs |

|

Max qty per large box |

40,000pcs |

Packing Label Sample

Note:

-

-

Material Code :Product ID.

-

P/N :Contents with "Order Information" in the specification.

-

Lot No. :Product data.

-

D/C :Product weeks.

-

Quantity :Packaging quantity.

-

Temperature Profile Of Soldering

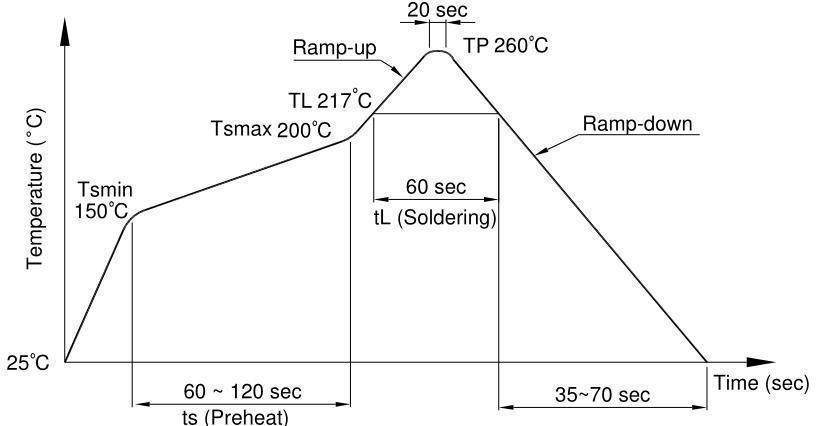

(1). IR Reflow soldering (JEDEC-STD-020C compliant)

One time soldering reflow is recommended within the condition of temperature and time profile shown below. Do not solder more than three times.

|

Profile item |

Conditions |

|

Preheat

- Time (min to max) (ts) |

150˚C 200˚C 90±30 sec |

|

Soldering zone - Temperature (TL ) - Time (t L ) |

217˚C 60 sec |

|

Peak Temperature |

260˚C |

|

Peak Temperature time |

20 sec |

|

Ramp-up rate |

3˚C / sec max. |

|

Ramp-down rate from peak temperature |

3~6˚C / sec |

|

Reflow times |

≤3 |

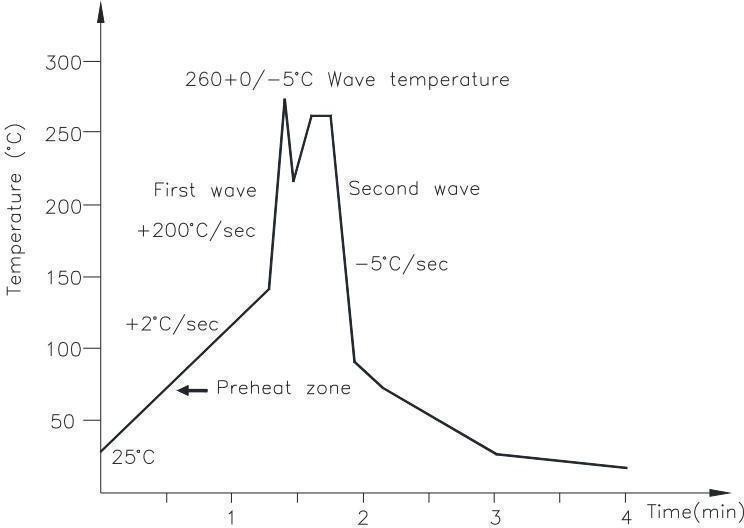

(2).Wave soldering (JEDEC22A111 compliant)

One time soldering is recommended within the condition of temperature.

|

Temperature Time |

260+0/-5˚C 10 sec |

|

Preheat temperature Preheat time |

25 to 140˚C 30 to 80 sec |

(3).Hand soldering by soldering iron

Allow single lead soldering in every single process. One time soldering is recommended.

Temperature

380+0/-5˚C

Time

3 sec max