English

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Română

Română Slovenski

Slovenski Српски

Српски Afrikaans

Afrikaans Беларус

Беларус Hrvatski

Hrvatski Монгол хэл

Монгол хэл Zulu

Zulu Somali

Somali O'zbek

O'zbek Hawaiian

Hawaiian

Home

PRODUCTS

Photoelectric sensor

Chip LED Photoelectric sensor

Top View White LED OR-W0603L4-YD-4T

PRODUCTS

New Products

Consume Grade Phototransistor Optocoupler OR-3H7-EN-V13

Consume Grade Phototransistor Optocoupler OR-3H7-EN-V13 Consume Grade Phototransistor Optocoupler OR-3H7-4-EN-V3

Consume Grade Phototransistor Optocoupler OR-3H7-4-EN-V3 Consume Grade Phototransistor Optocoupler OR-3H4-EN-V12

Consume Grade Phototransistor Optocoupler OR-3H4-EN-V12 Consume Grade Phototransistor Optocoupler OR-3H4-4-EN-V3

Consume Grade Phototransistor Optocoupler OR-3H4-4-EN-V3 Consume Grade Phototransistor Optocoupler ORPC-817-S-(SJ)

Consume Grade Phototransistor Optocoupler ORPC-817-S-(SJ) Consume Grade Phototransistor Optocoupler ORPC-817-S-(SJ)-EN-V0

Consume Grade Phototransistor Optocoupler ORPC-817-S-(SJ)-EN-V0- All new products

Top View White LED OR-W0603L4-YD-4T

This product doesn’t contain restriction substance, comply RoHS standard.

Product Description

lighting LED

1.Features

● Emitted Color : White.

● 1.6x0.8x0.4mm(0603) standard package.

● Suitable for all SMT assembly methods.

● Compatible with infrared and vapor phase reflow solder process.

● Compatible with automatic placement equipment.

● This product doesn’t contain restriction substance, comply RoHS standard.

2.Applications

● Indicator and backlighting.

● Flat backlight for LCD, switch and symbol.

● General use.

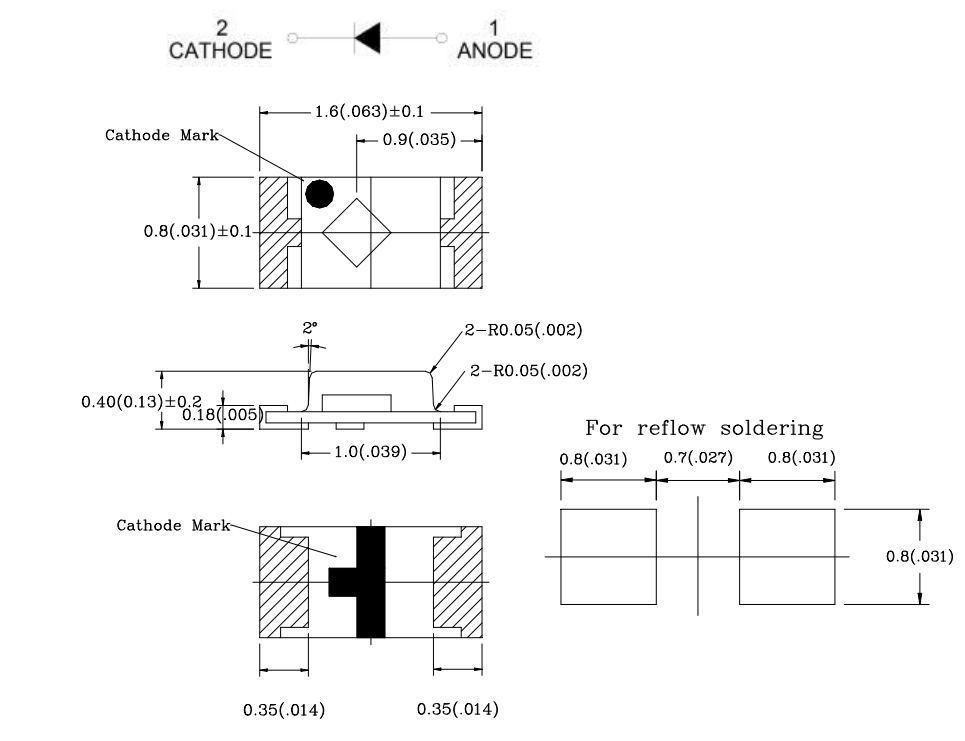

3.Package Outline Dimensions

Notes:

1).All dimensions are in millimeters (inches).

2).Tolerance is ± 0.10mm (0.004”) unless otherwise specified.

3).Specifications are subject to change without notice.

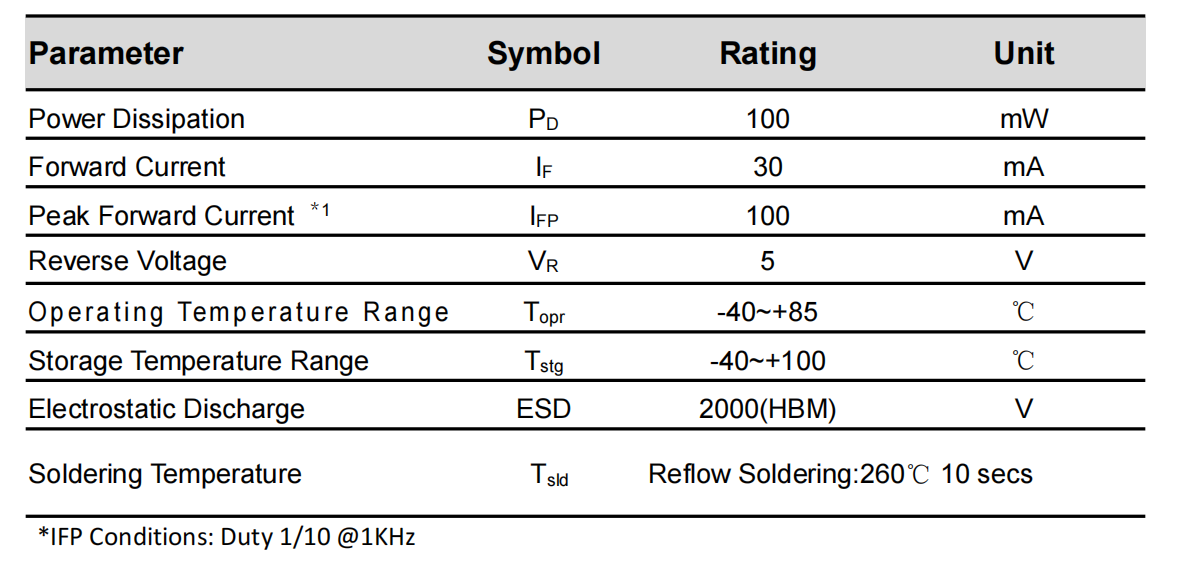

4.Absolute maximum ratings at Ta=25℃

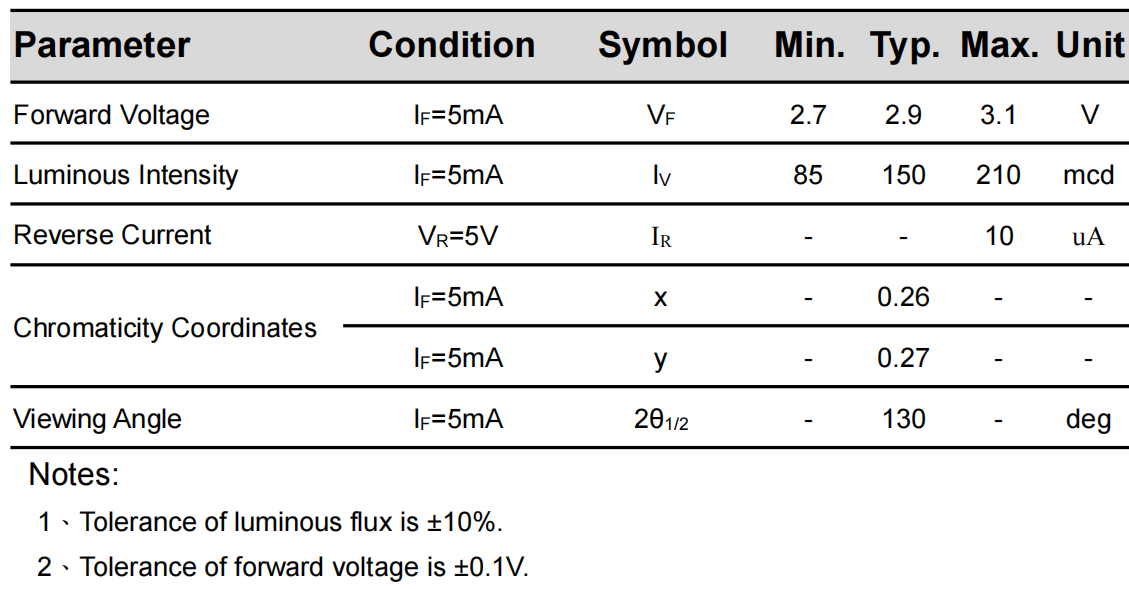

5.Electrical-optical characteristics at Ta=25℃

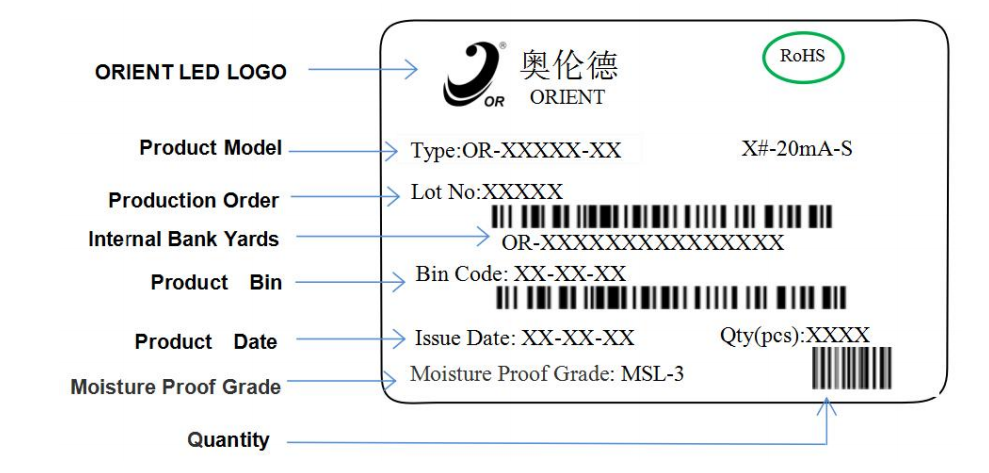

6.Label description

7.Precautions for use

1.Soldering

SMD LED encapsulation is very flexible, outside force easily demolish radiant surface and plastic, As soldering , Please handle with care!

1.1. With No-clean Flux, according to reflow soldering cure condition when soldering, Reflow soldering should not be done more than two times, simultaneity you must insure clean on the radiant surface. Otherwise, foreign objects can affect radiant color.

1.2. Don’t process manual soldering except repair. Recommended to be soldered with 25W Anti-static iron, The temp. of the iron should be lower than 300℃ and soldering time should not be done more than three seconds, at the same time iron can’t touch radiant surface and plastic.

1.3. Don’t twist LED in course of manual soldering and experiment, otherwise, the lights will not work possibly.

1.4. Please use the same BIN grade in one panel, and don’t mix the difference BIN grade in one panel when soldering. Otherwise, it will cause a serious uneven color problem.

1.5. Please control the sulfur content of solder paste and PCB.

1.6. Pb-free solder temp.-time profile as below:260℃Max

2.Cleaning

2.1. Don’t be cleaned with ultrasonic. Recommended to be wiped with isopropyl alcohol or pure alcohol, wiping time should not be more than one minute. LED must be placed at room temperature for fifteen minutes before using. After cleaning, you must insure clean on the radiant surface. Otherwise, foreign objects can affect radiant color.

2.2. LED can not be in contact with isoamyl acetate, trichloroethylene, acetone,sulfide, nitride, acid, alkali, salt. These matter can destroy LED

.

3.Sealing

3.1. Sealing glue can not contain sodium ion, sulfide, because these matter can affect fluorescence powder poisoning.

3.2. When using normal sealing glue, Use within 168 hours after opening

4.Storage

4.1. Don’t open the moisture proof bag before ready to use the LEDs.

4.2. The LEDs should be kept at 30℃ or less and 60%RH or less before opening the package. The max. storage period before opening the package is 1 year.

4.3. After opening the package, the LEDs should be kept at 30-35%RH or less, and it should be used within 3 days. If the LEDs should be kept at 30-35%RH or more, and it should be used within 4 hours.

4.4. If the LEDs be kept over the conditions of 20%, baking is required before mounting. Baking condition as below: 70±5℃ for 12 hrs for bulk goods, 105±5℃ for 1 hrs for roll goods.

4.5. The environment have no acid, alkali, corrosive gas, intensively shake and high magnetic field.

5.Static

5.1.Static and Peak surge voltage can destroy LED, Avoiding Instantaneous voltage when turn on or turn off the lights.

5.2. Please wear Anti-static wrist band, Anti-static glove, Anti-static shoes in the course of operation, and the equipment must be grounded.

6.Test

6.1. Customer must apply the current limiting resistor in the circuit so as to drive the LEDs within the rated current. Otherwise slight voltage shift maybe will cause big current change and burn out will happen.

6.2. Also, caution should be taken not to overload the LEDs with instantaneous high voltage at the turning ON and OFF of the circuit. Otherwise, The LEDs will be destroyed, testing methods as follows:

6.3. The reverse voltage mustn’t exceed 5v when lighting on or testing the LED, otherwise,The LEDs will be damaged.

7.Else

Radiant color of LEDs have a little change with the current, recommended that LED is used in series and resistance, when lighting, please don’t see directly radiant surface of LED, otherwise LED will burn eyes.